About

Project background

“Our aim is to develop an adapted, energy efficient and affordable process to thermo-chemically convert the municipal sewage sludge into useful biochar (charcoal from pyrolysis treatment) and synthetic gas (syngas). This technology will address the current problem of the small municipalities in managing their increasing amount of sewage sludge.”

The implementation of the European Directives for the treatment of water and wastewater (e.g. 86/278/EEC, 91/271/EEC) has improved the general quality and management of the waters across the member states, but has also created challenges for the cost-effective management and disposal of the increasing sewage sludge (more than 10 million tons of dried sludge is produced yearly within the 26 member states).

The European municipalities and their small Wastewater Treatment Plants (WWTPs) are currently facing the following problems:

- Compliance with stringent European Directives

- High cost of sludge treatment (storage, transport…) and lack of local infrastructures

- New technologies inadapted for smaller inputs

- Mistrust against sludge reuse

Pyrochar solution

PYROCHAR will develop a compact system to treat and dispose of the sewage sludge produced in small municipalities and their WWTPs (<10,000 p.e.).

The PYROCHAR system will dry the dewatered sludge and then use a slow pyrolysis technology to thermo-chemically convert the dried sludge into useful solid and gas by-products namely synthetic gas and biochar. Downstream, a hot gas clean-up unit followed by a combined heat & power (CHP) unit with gas turbine will convert the synthetic gas (syngas) in energy (heat and electricity) for the system. In addition, the by-product of small municipalities’ sewage sludge pyrolysis (biochar) contains a limited amount of heavy metals as compared to sludge from big industries. This makes it perfect for homologations and reuse – for example, in land spreading.

Clear commercial advantages will be that the sludge will be treated on-site, decreasing its total dewatered volume by more than 95% and hence decreasing also in more than 50% its operating & maintenance cost. Besides, the PYROCHAR system will reuse the calorific power of the sludge to fuel its own system, making the overall system highly energy efficient. Finally, the useful nutrients such as nitrate, phosphorus or potassium, will not be lost during the process but trapped in stable by-products, the biochar, with high economic value for the end users.

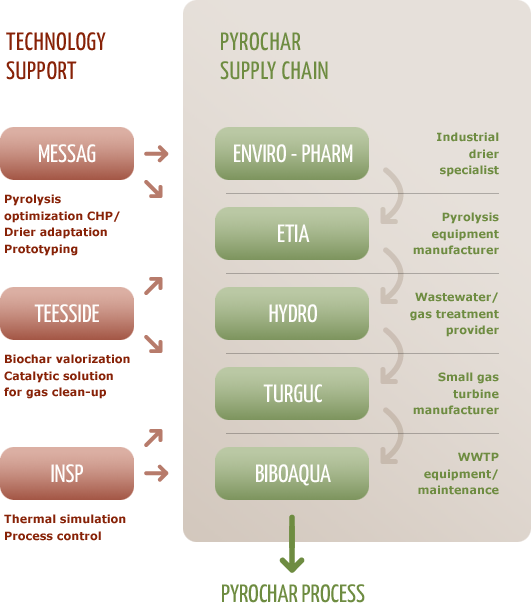

Pyrochar supply chain

The PYROCHAR project is supported by a strong Consortium of SMEs and research centers which form a well-defined supply chain: thermal treatment equipment (E.T.I.A., acting as coordinator, from France), sludge drier (Enviro-Pharm Ltd, Hungary), wastewater and gas treatment solution (Hydro Italia Srl, Italy), gas turbine (TURGUC, Turkey), wastewater treatment plant maintenance services (Biboaqua S.L., Spain). They are assisted by three research centres, selected according to their specific technical knowledge and expertise, i.e. biomass, biochar and gas clean-up technology (University of Teesside, the UK), flow simulation and control process (Tecnologías Avanzadas Inspiralia S.L., Spain), and thermal equipment optimization and prototyping (MESSAG, Switzerland).